The LONKEY circulator pumps, Series LRS, are specifically designed for heating systems. The pumpsar...

- E-mail us: lonkey@lonkey.com

- 24 Hour Service - 7 Days a Week

English

Brass Pump Head Circulation Pump Manufacturers

-

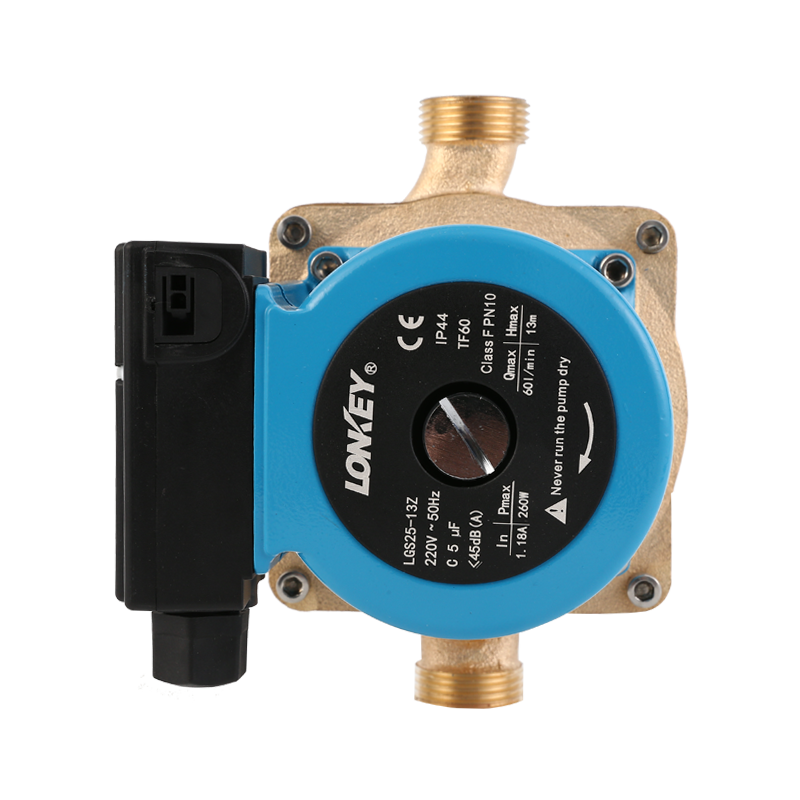

LGS25-13Z Brass Circulator Pump For Drink Water Domestic Water Circulation Bombas

Read MoreDomestic hot water circulators, constant speed sealless pumps for pipe installation. Anti-jam motor....

Brass Pump Head Circulation Pump Industry Knowledge Extension

What Are the Advantages of Using Brass as the Pump Head of the Circulation Pump?

Using brass to manufacture the pump head of the circulation pump has the following advantages:

1. Good corrosion resistance: Brass has good corrosion resistance and is not easily affected by corrosive substances in water, so it can maintain the performance and life of the circulating pump.

2. Good wear resistance: The brass pump head is relatively hard, the surface is smooth, and it is not easy to generate friction, so it will not wear out during long-term use.

3. Good thermal conductivity: Brass is a metal material with good thermal conductivity, which can transfer the heat transferred by the circulating pump to the water more effectively.

4. Good pressure resistance: Brass material has good pressure resistance and can withstand a certain water pressure, so as to maintain the normal working state of the circulating pump.

5. Beautiful appearance: The brass pump head has an exquisite appearance, which can improve the aesthetics of the circulating pump and make it more in line with people's aesthetic needs.

It should be noted that the pump head made of brass is more expensive than the pump head made of other materials, but because of its better durability and longer service life, it can save more maintenance and replacement costs in long-term use.

What Is Brass Pump Head Circulation Pump and How Does It Work?

Brass pump head circulation pump is a kind of circulation pump, usually used in water circulation system, such as home heating system, solar water heating system, swimming pool water circulation system, etc. It consists of a pump head made of brass and an electric motor that moves the water circulation to the desired position. Brass pump heads are generally considered a high quality, high durability and long life choice for some of the more demanding environments. Circulator pumps are usually designed to be installed on pipes to help push the water flow, increasing the velocity and flow of water, thus increasing the efficiency and performance of the system.

Its working principle is to drive the impeller to rotate through the motor to generate centrifugal force so that the water flows into the suction hole in the center of the pump head. Through the rotation of the impeller and the action of centrifugal force, the water is pushed to the outlet of the pump head, thus forming a water circulation flow.

Specifically, the working process of the brass pump head circulation pump is as follows:

1. Before starting to work, fill the inside of the pump head with water, and connect the suction port of the pump head to the circulating pool or other water sources.

2. When the motor starts, the driving impeller starts to rotate, and the water is sucked into the suction hole in the center of the pump head.

3. Under the action of the impeller rotation, the water is pushed to the water outlet of the pump head by the centrifugal force and enters the water pipeline, thereby forming a water circulation flow.

4. When the circulating water reaches the set water level or flow, the flow of circulating water can be adjusted by controlling the start and stop of the motor.

5. When you need to stop working, just turn off the power.

English

English Español

Español

+86-576-86330112

+86-576-86330112