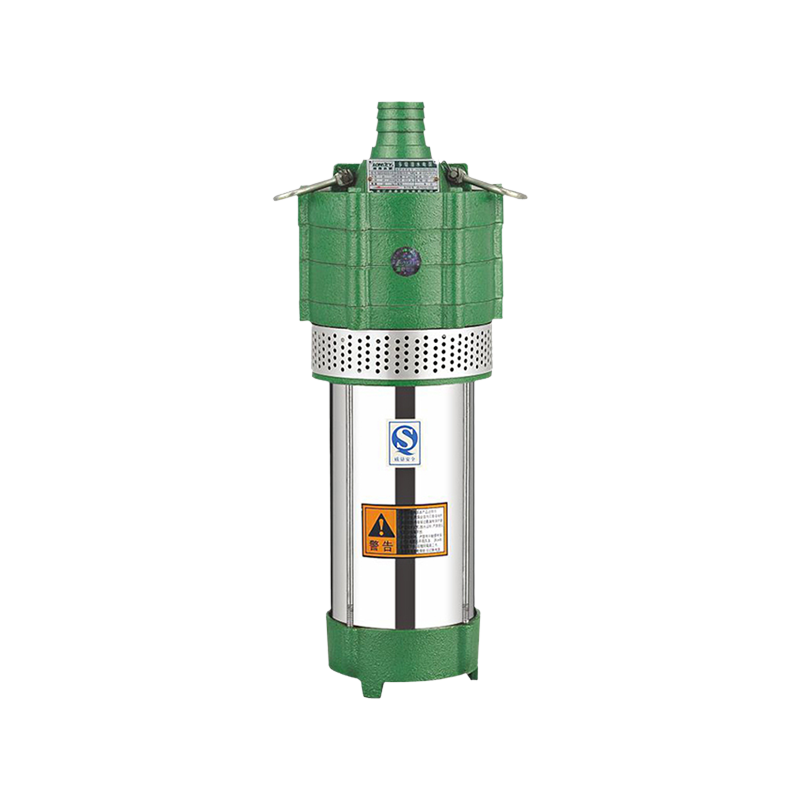

QD series submersible electric pump consists of three parts: water pump, seal and motor. The motor i...

- E-mail us: lonkey@lonkey.com

- 24 Hour Service - 7 Days a Week

English

QD Multi-Stage Submersible Pump Manufacturers

QD Multi-Stage Submersible Pump Industry Knowledge Extension

What Is QD Multi-stage Submersible Pump?

QD multistage submersible pumps are a common type of water pump used to pump water from deep wells, wells, or other water sources. It is composed of multiple centrifugal pumps cascaded, each pump has a rotor and a stator, through the way of multi-cascade to achieve high head and high-pressure delivery.

QD multistage submersible pump usually consists of pump main body, underwater cable, control box and protector and other components. The main body of the water pump is usually made of stainless steel or cast iron, which is corrosion-resistant and wear-resistant. The underwater cable is used to connect the water pump and the control box, and the control box is used to control the start, stop and operation status of the pump.

QD multi-stage submersible pumps are widely used in industry, agriculture, civil and other fields, such as underground water source development, urban water supply, sewage treatment, farmland irrigation, etc. It has the advantages of compact structure, stable operation, high efficiency, long service life, etc. It is a very practical and reliable water pump equipment.

What Are the Advantages and Features of QD Multi-stage Submersible Pump?

QD multi-stage submersible pump has the following advantages and characteristics:

1. Multi-stage structure: QD multi-stage submersible pump adopts a multi-stage structure design, which can increase its head and pressure, while reducing power consumption and energy waste, thereby improving its efficiency and service life.

2. Submersible design: The pump is a submersible design, which can be directly placed in the liquid to run, which reduces the resistance of the pipeline and the process of introducing the liquid into the pump, and improves the efficiency of the pump.

3. Energy saving and environmental protection: QD multi-stage submersible pump adopts advanced hydraulic principles, combined with optimized motor design, can achieve high efficiency, low noise, low vibration operation, and can save energy and reduce carbon emissions at the same time, and has good environmental protection performance.

4. Corrosion-resistant materials: The main parts of the pump are made of high-strength stainless steel, which can resist certain corrosion and oxidation and prolong the service life of the pump.

5. Easy installation and maintenance: QD multi-stage submersible pump has a simple structure, small size, lightweight, and is easy to install and move; at the same time, the maintenance and maintenance of the pump are relatively simple, and only need regular cleaning and replacement of wearing parts.

6. Wide application: QD multi-stage submersible pump is suitable for various liquid transportation occasions, such as industrial, civil, agricultural, municipal and other fields, and can be used to transport different media such as clean water, sewage, and seawater.

How to maintain QD Multi-stage Submersible Pump?

1.Regular Visual Inspections: Conduct routine visual inspections of the pump, motor, and connections. Look for signs of leaks, corrosion, wear, or damage. Address any issues promptly.

2.Clean the Pump Housing: Keep the pump's exterior clean and free from dirt, debris, and dust. Cleaning the pump housing helps maintain optimal heat dissipation.

3.Inspect Impellers and Stages: Inspect the impellers and stages for wear, damage, or clogs. Ensure that the impellers are clean and free from obstructions.

4.Check Seals and Gaskets: Examine the seals and gaskets for signs of wear, cracks, or leakage. Replace any damaged seals or gaskets to prevent water leaks.

5.Monitor Motor Performance: Regularly monitor the motor's performance, including temperature, vibrations, and noise levels. Unusual noises or excessive heat could indicate a problem.

6.Lubrication: Some components, such as bearings, may require lubrication. Follow the manufacturer's recommendations for lubrication intervals and types of lubricants to use.

7.Inspect Cable and Connectors: Examine the power cable and connectors for damage or wear. Ensure that cable glands are properly sealed to prevent water ingress.

8.Pressure Tank Inspection: If the pump is connected to a pressure tank, inspect the tank's pressure settings and the air charge in the tank. Adjust as needed to maintain proper pressure.

9.Electrical Connections: Inspect the electrical connections, wiring, and plugs for damage or loose connections. Ensure the motor is operating within the correct voltage range.

10.Replace Worn Parts: Over time, components such as seals, impellers, and bearings may wear out. Replace these parts according to the manufacturer's recommended intervals or if you notice decreased pump performance.

English

English Español

Español

+86-576-86330112

+86-576-86330112